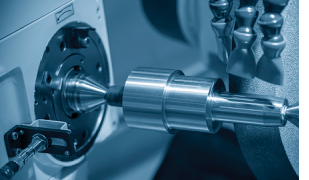

Flat running in outer round grinding wheel

Category:

key word:

Flat running in outer round grinding wheel

Tel:

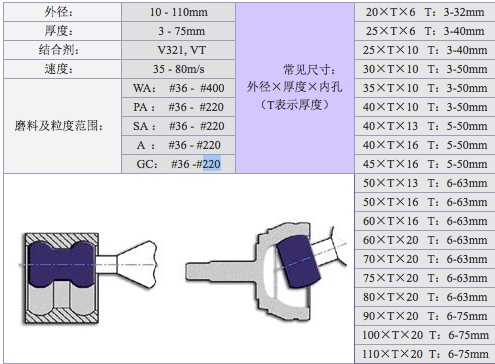

One of the important properties of a flat grinding wheel is its hardness, which must be harder than the material to be processed. The Mohs hardness tester is commonly used to measure the hardness of various abrasives. Another important property of abrasives is toughness or volumetric strength. This performance can be controlled by changing the mixing amount, purity, particle size, and crystal structure of the raw materials to be suitable for various applications

The manufacturing of abrasive products requires crushing and screening of all raw materials for flat grinding wheels, except for powdered talc and iron oxide. The screening particle size should be 4-900, with a diameter of about 6 millimeters (mm) to 6 micrometers (1 thousandth of a millimeter) or finer. Grinding wheel is the main abrasive product, which is made by mixing abrasive and binder in a certain proportion, molding and sintering, and also requires shaping, balancing, and overspeed testing.

Sandpaper and sandpaper are another type of abrasive product with high production capacity. They are made by bonding abrasive particles to the base material (cloth or paper), and then cutting them into different specifications after drying. Others are powdered or granular abrasives that need to be processed through certain processes after screening, such as grinding or polishing abrasives, usually supplemented with mineral oil paste or wax and other auxiliary materials to meet the needs of different working conditions

User benefits

User benefits

★ High grinding performance is achieved through artificial pores, thus improving grinding performance

★ By using special high concentration sintered alumina, ideal wear consumption is achieved, thereby extending the service life of the grinding wheel

Grinding time can be reduced by 30%, and the dressing cycle can be extended by 10 times

★ Extremely high dimensional accuracy

★ Without sulfurization treatment, it can achieve super grinding performance without the problem of coolant sulfurization pollution

★ By using our organic combination of binders, abrasives, and microstructure, we have achieved immediate success

Related Products