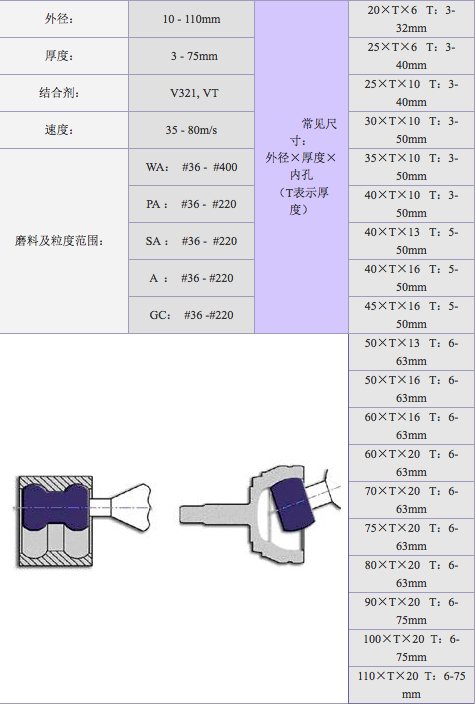

Internal grinding wheel

Category:

key word:

Internal grinding wheel

Tel:

Internal sanding wheels can be used to make various complex shapes and special requirements grinding tools. Due to the low curing temperature of resin bonded grinding tools, they can be hardened at room temperature with a small shrinkage rate, making them suitable for making various complex shapes and special requirements grinding tools. For example, using glass fiber reinforced resin grinding wheels, porous resin grinding wheels with easy chip removal and good heat dissipation, and grooved grinding wheels; Bolt fastening grinding wheels, electrolytic grinding wheels, and polishing grinding wheels for improving grinding process conditions; And irregular grinding wheels such as cylindrical, bowl shaped, butterfly shaped, etc. Widely applicable, due to the variety of new resin binders, resin grinding tools with various strengths and properties can be made.

Therefore, the inner grinding wheel can be widely used in processes such as rough grinding, cutting, semi precision grinding, precision grinding, polishing, etc. Resin grinding tools have high bonding strength, high operating speed, impact resistance, and are suitable for rough and rough grinding processing; Resin grinding tools have good toughness and are suitable for cutting and processing procedures; Resin grinding tools have good elasticity and certain polishing properties, and can be used for precision grinding and polishing processing. Resin grinding tools have low heat resistance and are prone to wear, making them suitable for flat and precision grinding processes. Beneficial for preventing burns on the ground workpiece, resin binders have lower heat resistance and can reduce or avoid the phenomenon of burning on the workpiece.

User benefits

★ High grinding performance is achieved through artificial pores, thus improving grinding performance

★ By using special high concentration sintered alumina, ideal wear consumption is achieved, thereby extending the service life of the grinding wheel

Grinding time can be reduced by 30%, and the dressing cycle can be extended by 10 times

★ Extremely high dimensional accuracy

★ Without sulfurization treatment, it can achieve super grinding performance without the problem of coolant sulfurization pollution

★ By using our organic combination of binders, abrasives, and microstructure, we have achieved immediate success

Related Products