Centerless grinding wheel

Category:

key word:

Centerless grinding wheel

Tel:

Heartless grinding wheels are widely used in industry, especially when processing high-precision or low roughness parts or particularly hard parts, abrasives and grinding tools are essential. In addition, grinding wheels are also essential tools for sharpening cutting tools and cutting hard materials. In the automotive manufacturing industry, the tight fit between piston rings and cylinders, valves and valve seats, as well as the accuracy of transmissions and gears, all require the use of abrasives and grinding tools to ensure.

Other related new products, such as media for plastic bonded rolling mills, save time for deburring a large number of parts and improve productivity. The production technology of abrasives has made significant progress. Superhard abrasive tools, with their excellent grinding performance, have been widely used in various aspects of grinding technology and have become the foundation for technological advances such as ultra precision grinding, efficiency grinding, difficult to machine material grinding, high-precision forming grinding, grinding automation, and unmanned technology. The efficiency of diamond grinding wheels has increased fourfold compared to 14 years ago; The total cost of zirconia alumina grinding wheels used in steel mills is only 25% of that in 1948, and the speed has increased by 7 times. The current problem is that the basic theory of grinding action is not yet clear and needs further research; The specifications of the products are complex and there are many varieties, which are not easy to simplify.

Detailed introduction:

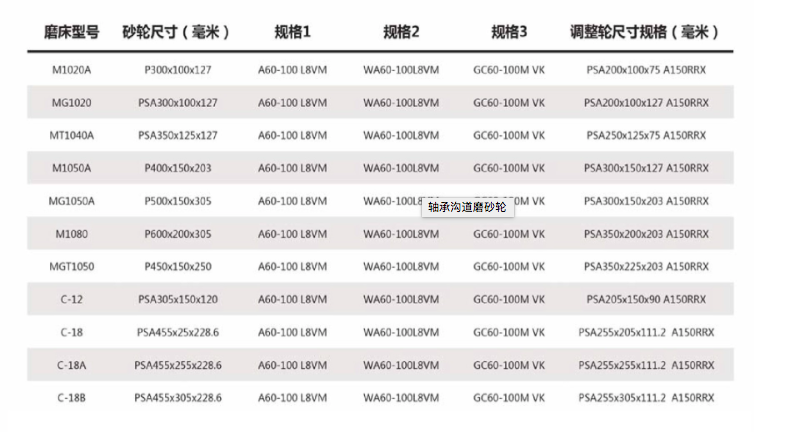

Heartless grinding wheel is a type of grinding wheel mainly made of 38A, A, PA, GC or mixed abrasives as raw materials. It has the characteristics of high grinding efficiency and good machining accuracy, and can be matched with imported and domestic centerless grinders such as 1020, 1040, 1060, etc., to process bars and shafts with different accuracies.

Purpose of Heartless Grinding Wheel:

Suitable for precision and ultra precision grinding of cylindrical workpieces using various centerless grinding machines. For example: shock absorber piston rod, locomotive fork inner tube, steering gear rod, rocker arm rod, engine valve, nitrogen cylinder, gas spring, nitrogen gas spring, printer axis, various rods in hydraulic parts, various pipe fittings in photocopiers, chrome plated rod, etc

The motion of the workpiece is jointly controlled by the guide wheel, grinding wheel, and pallet, with the control of the guide wheel playing a major role. The center lines of the grinding wheel and the guide wheel are generally on the same horizontal line, and the center line of the workpiece needs to be higher than the center line of the grinding wheel and the guide wheel, otherwise the problem of the workpiece not being round may occur.

Manufacturing scope:

Material: A, WA, PA, GC, C and other mixed materials

Particle size: 36 # -320 # to coarse

Outer diameter: 50-900 (mm)

Thickness: 1-300 (mm)

Inner diameter: 3-508 (mm)

Maximum linear velocity: 60 (m/s)

Heartless frosted wheel

The demand for abrasives and grinding tools is the highest in the manufacturing industry for bearing processing. Qingdao Yibaibai Abrasives and Grinding Tools products cover the entire bearing manufacturing process, such as end face grinding of bearing rings and rollers, centerless grinding, groove grinding of inner and outer rings, and inner circular grinding of bearings.

Selection reference

A abrasive is selected for grinding the inner and outer four of ordinary carbon steel shafts and bearings

Precision grinding of alloy steel shafts and bearings using WA abrasives for internal and external drawings

Use GC store materials for micro motor shafts

The grain size and hardness of the grinding wheel are adjusted according to the requirements of the workpiece being ground

Unless otherwise specified, the standard grinding wheel has a working speed of 35m/s, and high-speed grinding wheels can also be ordered

Related Products