The Organic Characteristics and Applications of Grinding Tools

Release time:

2024-06-25

Due to the low hardening temperature of resin bonded grinding tools, they can harden at room temperature and have a small shrinkage rate, making them capable of producing grinding tools with various complex shapes and special requirements.

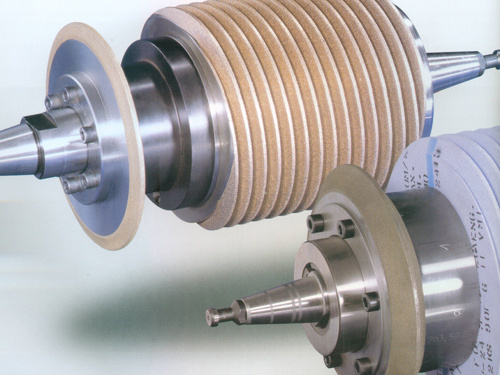

Due to the low hardening temperature of resin bonded grinding tools, they can harden at room temperature and have a small shrinkage rate, making them capable of producing grinding tools with various complex shapes and special requirements. For example, using resin grinding wheels reinforced with glass fiber, porous resin grinding wheels with easy chip removal and good heat dissipation, and grooved grinding wheels; Bolt fastening grinding wheels, electrolytic grinding wheels, and polishing grinding wheels to improve grinding process conditions; And irregular grinding wheels such as cylindrical, bowl shaped, and butterfly shaped. Widely applicable, due to the variety of new resin binders, resin grinding tools with various strengths and properties can be made.

Therefore, it can be widely used in processes such as rough grinding, rough grinding, cutting, semi precision grinding, precision grinding, polishing, etc. Resin grinding tools have high bonding strength, high usage speed, impact resistance, and are suitable for rough and rough grinding processing; Resin grinding tools have good toughness and are suitable for cutting and processing processes; Resin grinding tools have good elasticity and certain polishing properties, and can be used for precision grinding and polishing processing. Resin grinding tools have low heat resistance and are prone to wear, making them suitable for flat grinding and precision machining. Beneficial for preventing burns on ground workpieces, resin binders have lower heat resistance and can reduce or avoid the phenomenon of burns on workpieces. The heat generated during the grinding process of the workpiece first carbonizes the resin, causing the passivated abrasive to automatically detach and expose new sharp abrasive particles, reducing the heat in the grinding area and avoiding workpiece burns.