Types and properties of polishing abrasives

Release time:

2024-06-25

One of the important properties of abrasives is their hardness, which must be harder than the material to be processed. Mohs hardness testers are commonly used to measure the hardness of various abrasives. Another important property of abrasives is toughness or volumetric strength.

One of the important properties of abrasives is their hardness, which must be harder than the material to be processed. Mohs hardness testers are commonly used to measure the hardness of various abrasives. Another important property of abrasives is toughness or volumetric strength. The mixing amount, purity, particle size, and crystal structure of the raw materials can be changed to control this performance, making it suitable for various applications.

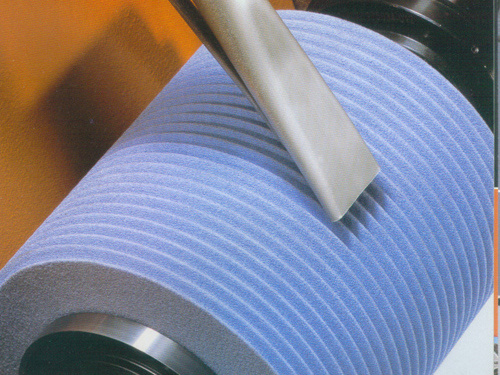

The manufacturing of abrasive products requires crushing and screening of all raw materials, except for powdered talc and iron oxide. The screening particle size should be 4-900, with a diameter of approximately 6 millimeters (millimeters) to 6 micrometers (one thousandth of 1 millimeter) or finer. Grinding wheels are the most important abrasive products, which are mixed with abrasives and binders in a certain proportion, molded and sintered, and finally subjected to shaping, balancing, and overspeed tests. Sandcloth and sandpaper are another type of high-yield abrasive products, which are made by bonding abrasive particles onto the base material (cloth or paper), drying them, and cutting them into different specifications of products. Other abrasives are in powder or granular form, and after screening, they need to undergo certain process treatments, such as grinding or polishing abrasives, usually supplemented with mineral oil ointments or waxes to meet the needs of different working conditions.